-

Home

-

Products

-

Induction Heater

-

Induction Heater Control Board

-

Induction Heating Equipment

-

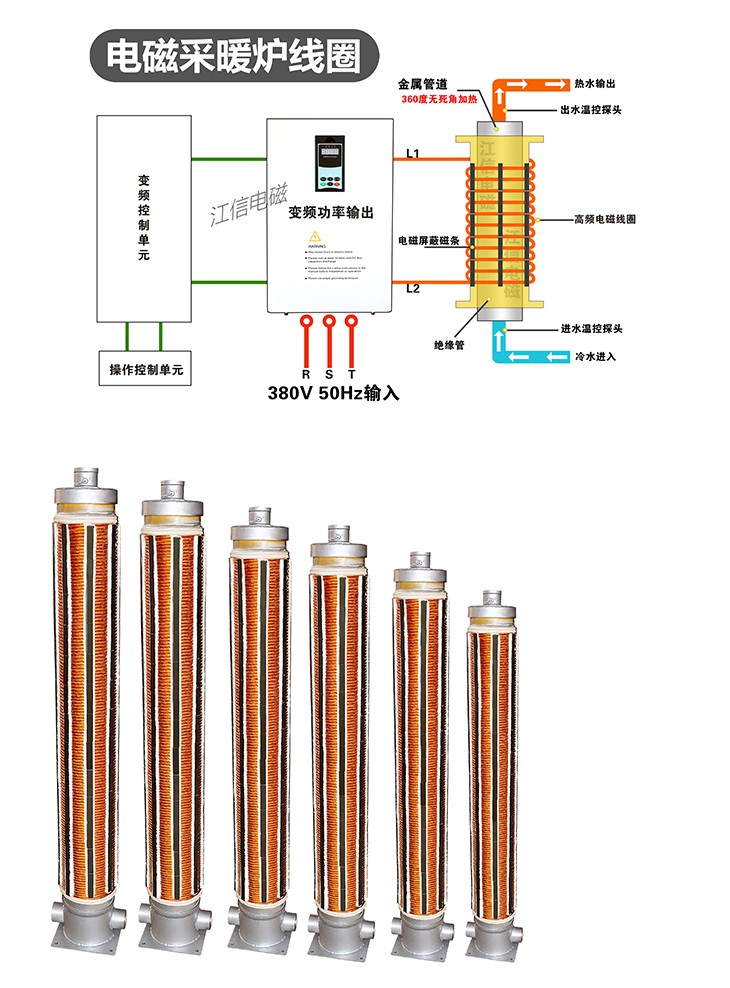

Induction Heating Water Boiler

-

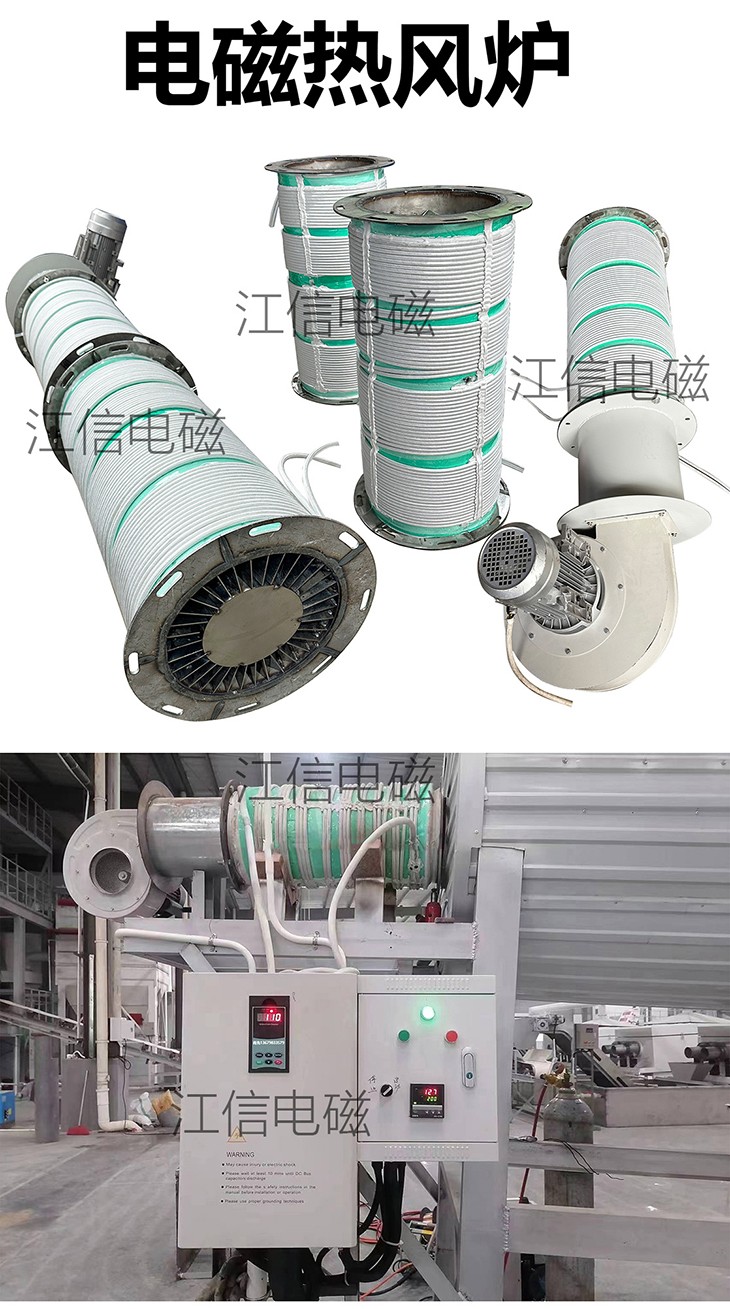

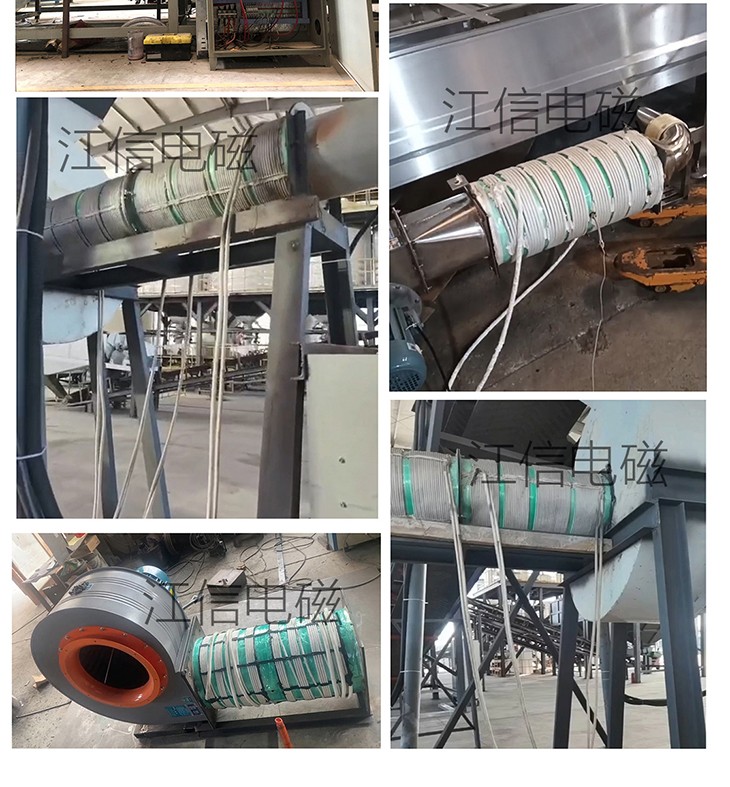

Induction Heating Hot Air Generator

-

Induction Water Heater

-

Induction Room Heater

-

Wall-mounted Induction Heating Water Boiler

-

induction Water Boiler

-

Induction Steam Generator

-

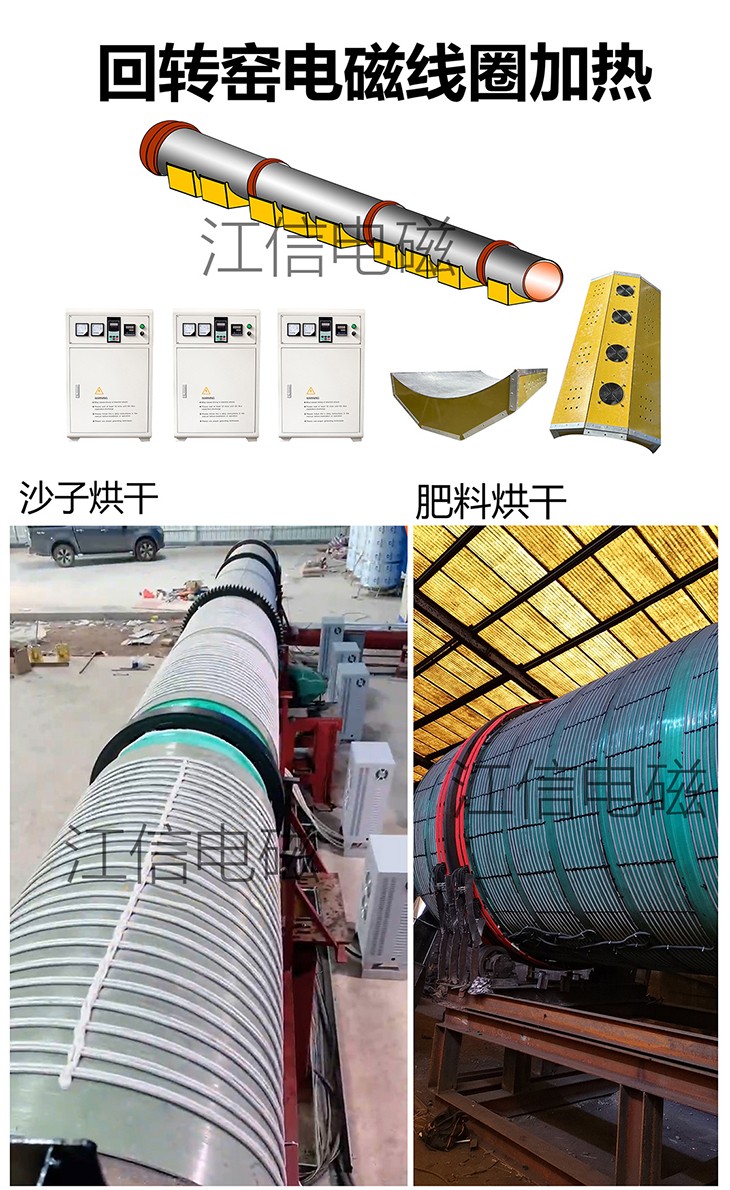

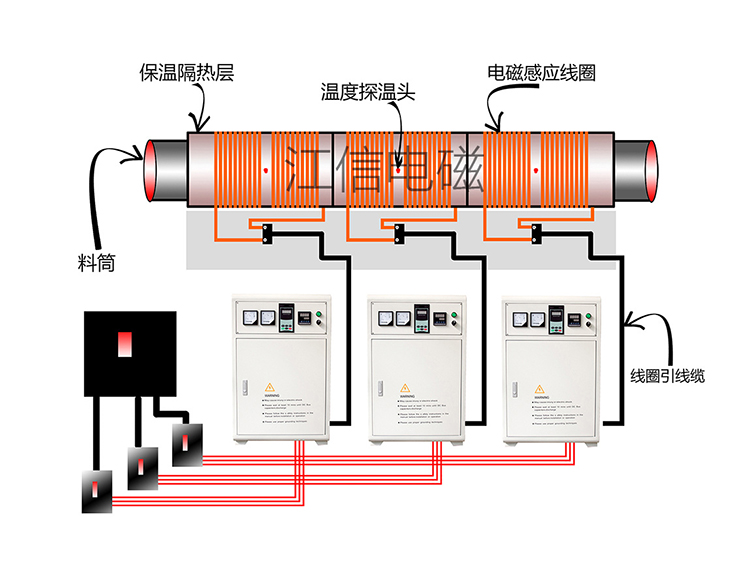

Induction Heating Coil

-

Induction Heater Manufacturer

-

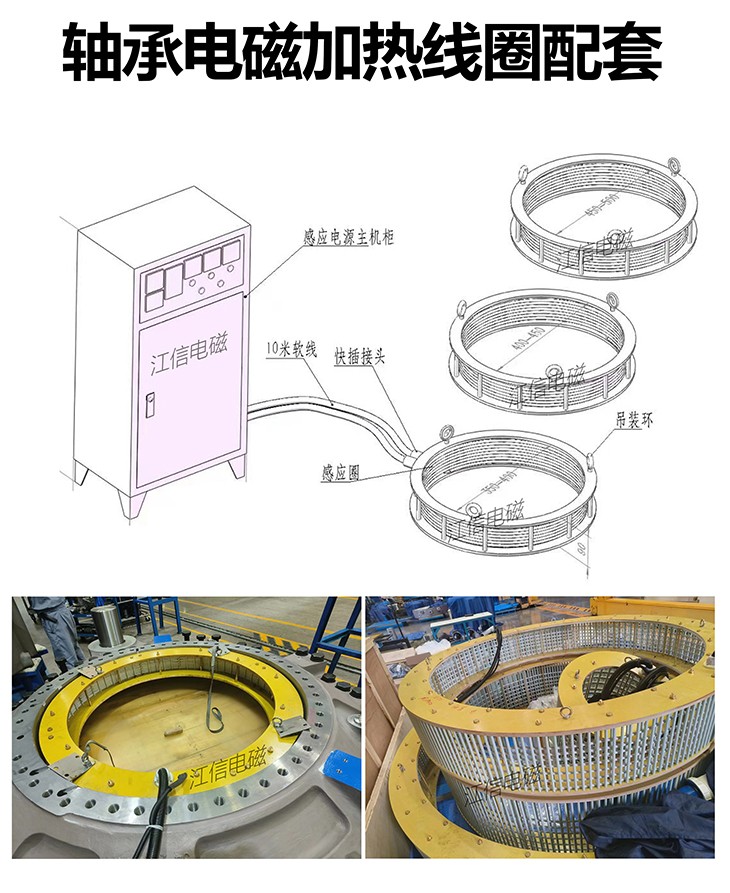

Bearing Induction Heater

-

Induction Welding Machine

-

Induction Heating Machine

-

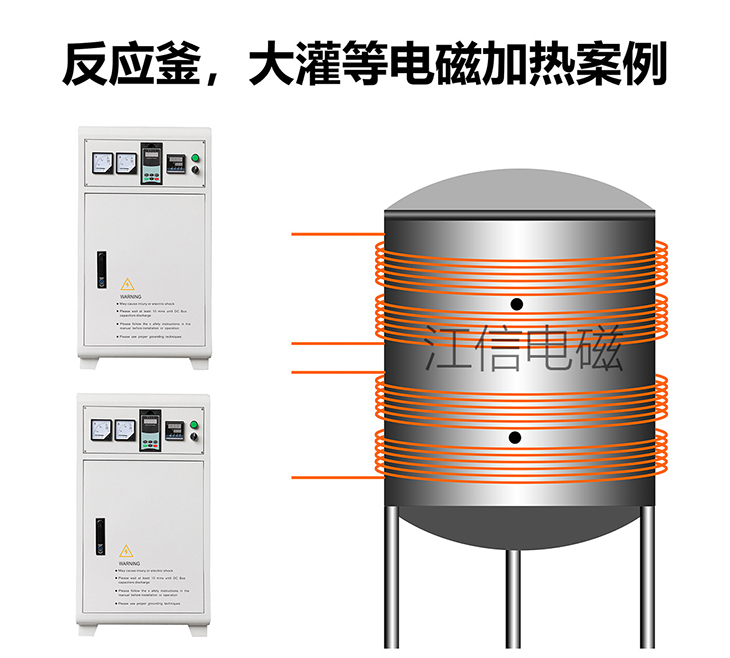

Customized electromagnetic induction heating coil

-

Induction Heater

-

News

-

Case

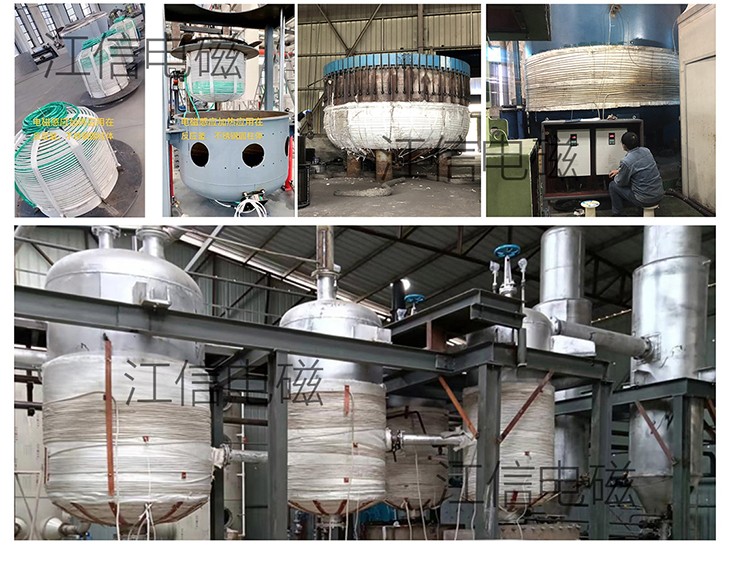

- Factory Show

-

Contact Us

- About Us

-

Video