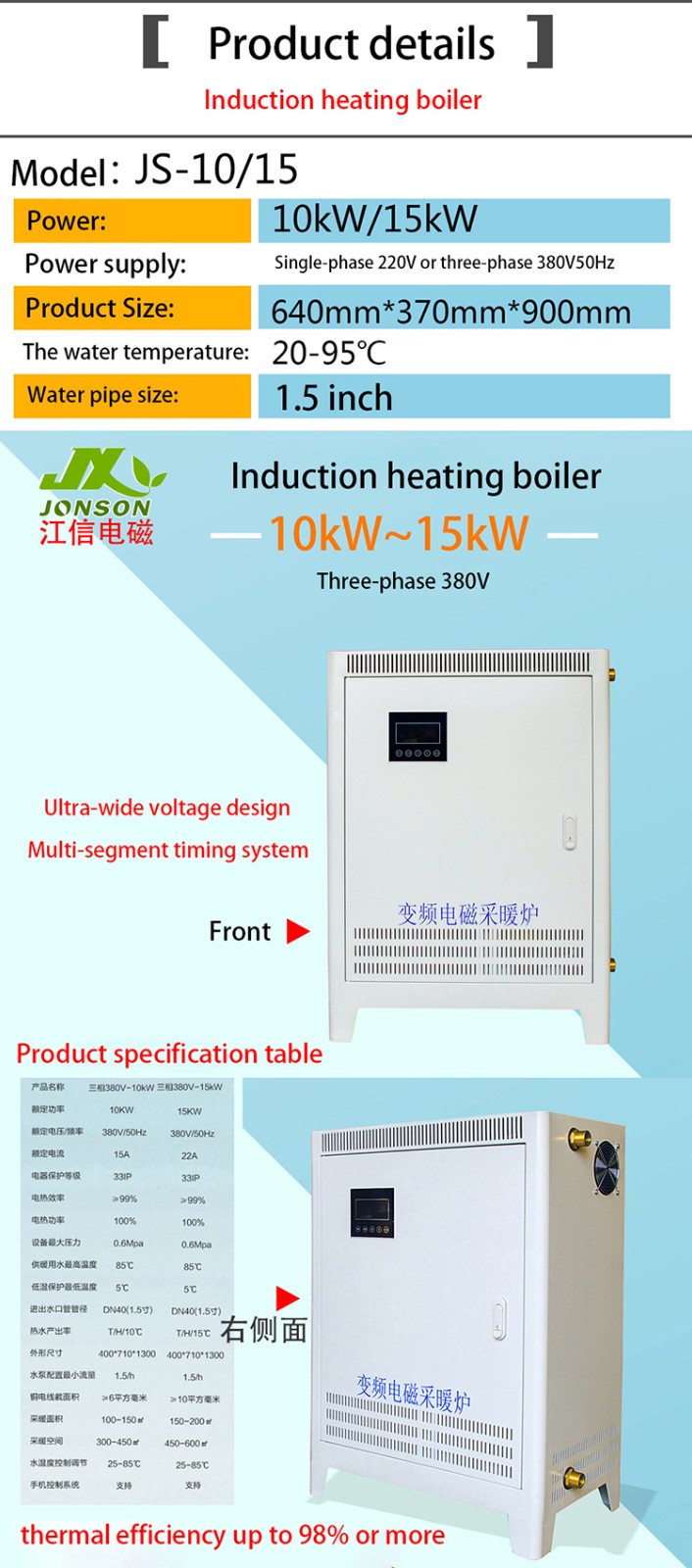

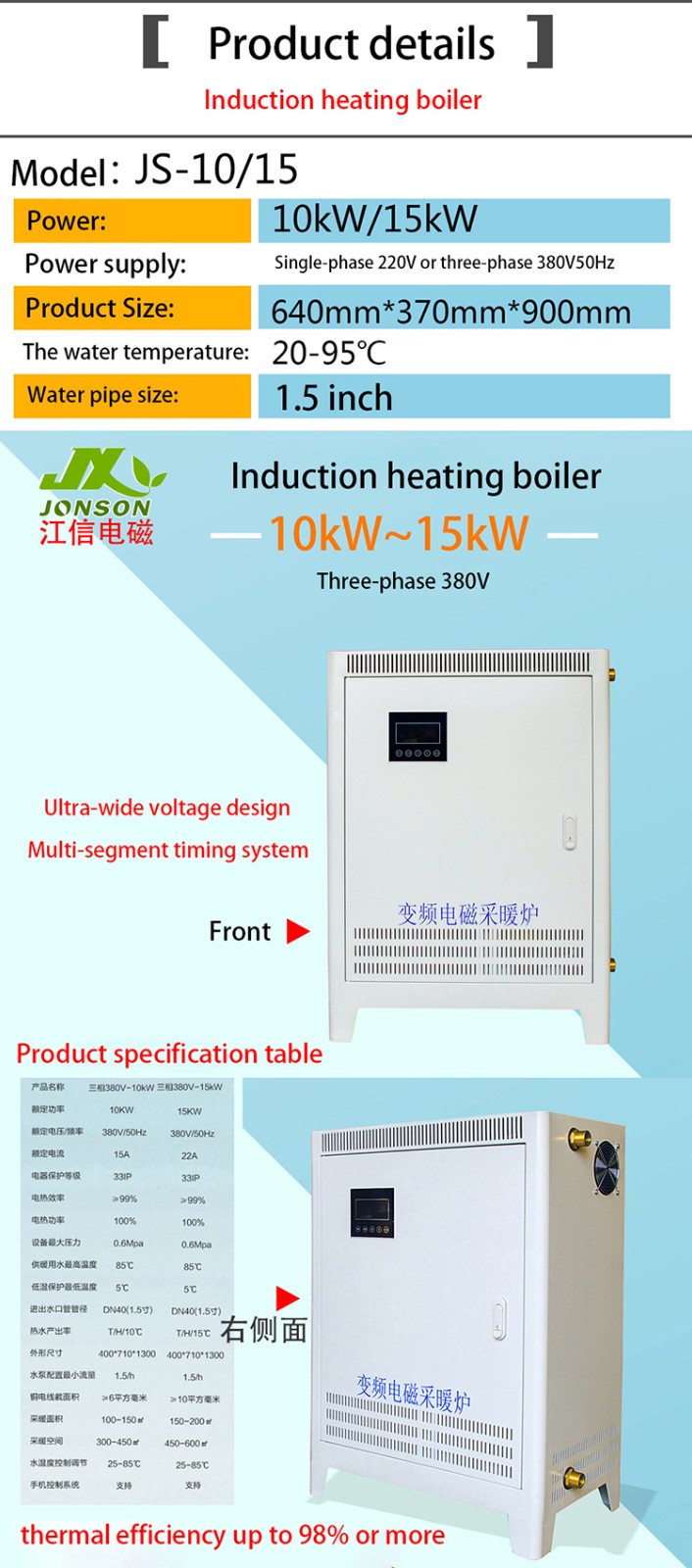

10/15kw Electromagnetic Induction Heating Furnace

Electromagnetic induction heating furnace: application and advantages of 10/15kw

Electromagnetic induction heating furnace is a widely used heat source equipment in industrial production. It converts electrical energy into thermal energy through the principle of electromagnetic induction, achieving heating of the workpiece. This article will focus on the 10/15kw electromagnetic induction heating furnace, exploring its application, advantages, and precautions.

1﹜ Application scenarios

The 10/15kw electromagnetic induction heating furnace is suitable for heat treatment, melting, forging, and hot forming processes of various metal materials. In industries such as mechanical manufacturing, automotive manufacturing, aerospace, and mold manufacturing, electromagnetic induction heating furnaces have become indispensable tools.

2﹜ Advantages

Efficient and energy-saving: Compared to traditional flame or electric heating methods, electromagnetic induction heating furnaces have higher heating efficiency and can significantly reduce energy consumption.

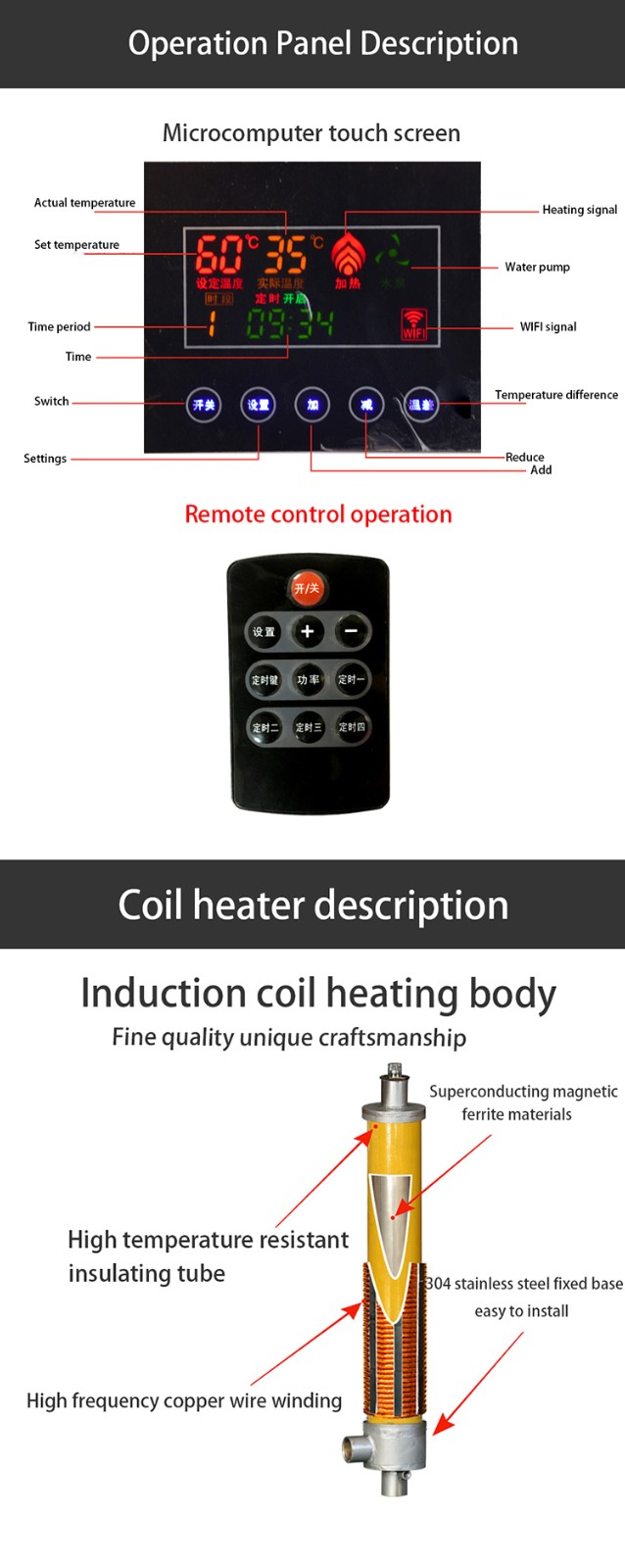

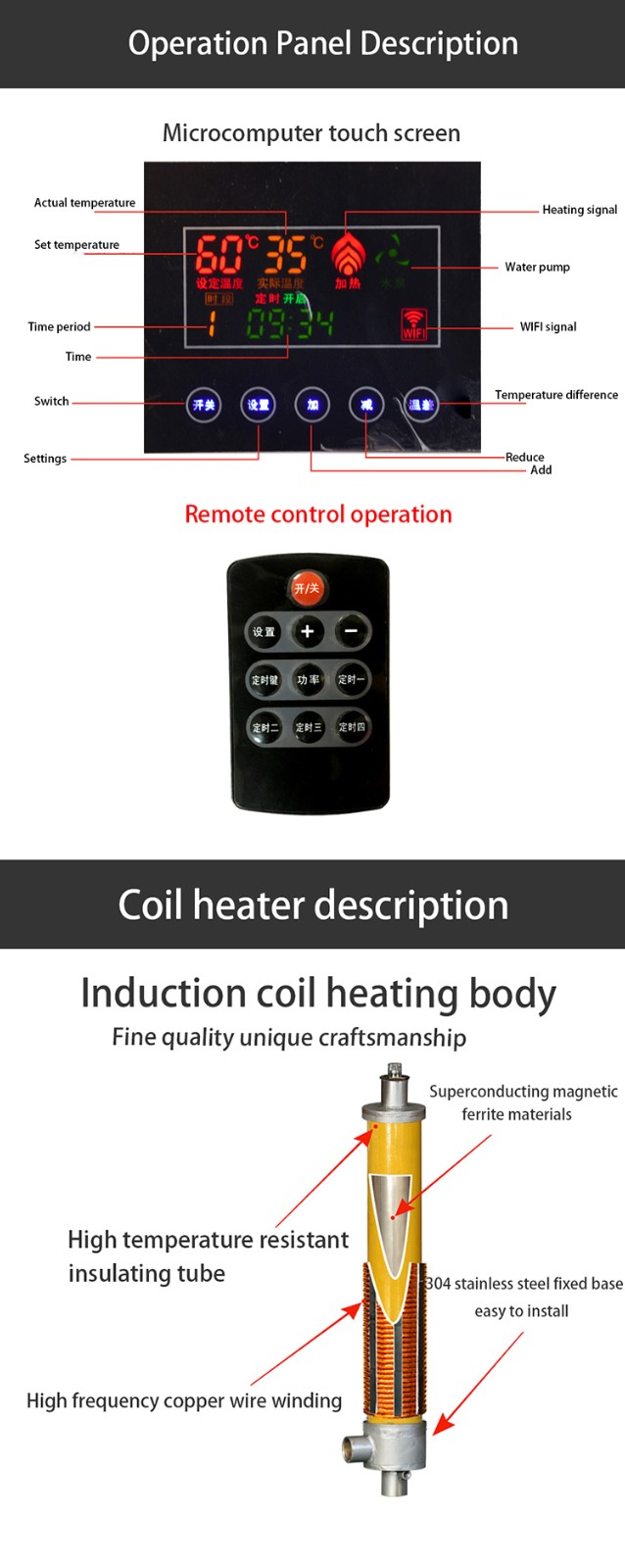

Accurate temperature control: The electromagnetic induction heating furnace can control the heating temperature by adjusting the current, with high accuracy and good stability.

Environmentally friendly and pollution-free: Electromagnetic induction heating produces no harmful gases or smoke, making it environmentally friendly.

Easy to operate: With a high degree of automation, it can achieve unmanned operation and reduce labor costs.

Long equipment lifespan: The electromagnetic induction heating furnace has a simple structure, low maintenance cost, and long equipment lifespan.

3﹜ Precautions

Ensure stable power supply: To ensure the normal operation of the heating furnace, it is necessary to ensure the stability of the power supply and avoid excessive voltage fluctuations.

Regular maintenance: To ensure the long-term stable operation of the equipment, regular maintenance and upkeep should be carried out.

Operation safety: Operators should understand and comply with the operating procedures of electromagnetic induction heating furnaces to ensure personal safety.

Metal foreign object treatment: During the heating process, it should be ensured that there are no metal foreign objects in the workpiece to avoid equipment damage.

Rated power: 10kW / 15kw

Rated voltage and frequency: 380V / 50Hz

Voltage adaptation range: 340 ~ 430

Applicable ambient temperature: - 20 ~ 40 ∼ C

Applicable ambient humidity: ≒ 95%

Power regulation range: 25% ~ 100%

Heat conversion efficiency: ≡ 90%

Effective power: 10kW / 15kw

Operating frequency: 50Hz

Ten advantages of 17勛圖 frequency conversion heating furnace:

1. Environmental protection and zero emission: no combustion, no waste, no harmful gas emission, and no pollution. This is unmatched by coal-fired, oil-fired and gas-fired boilers;

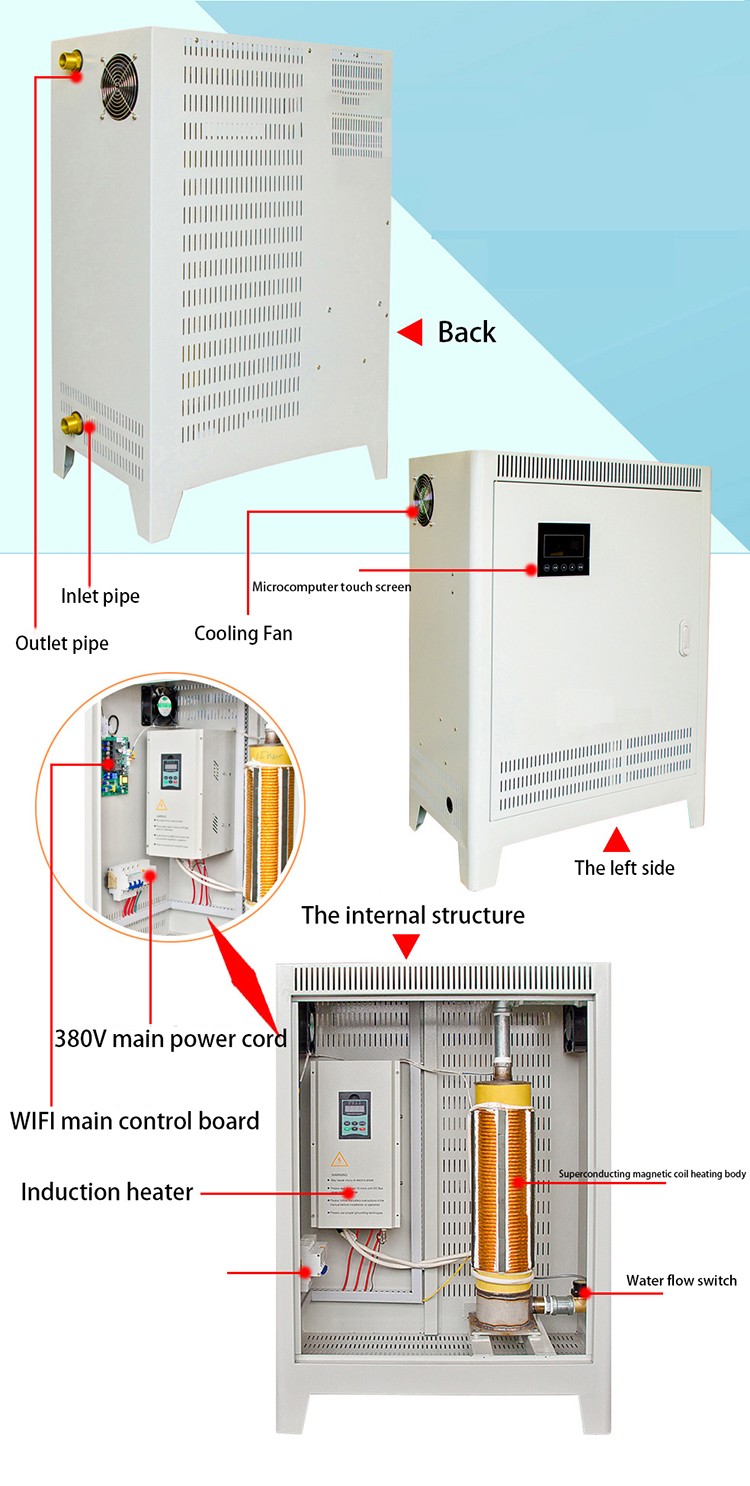

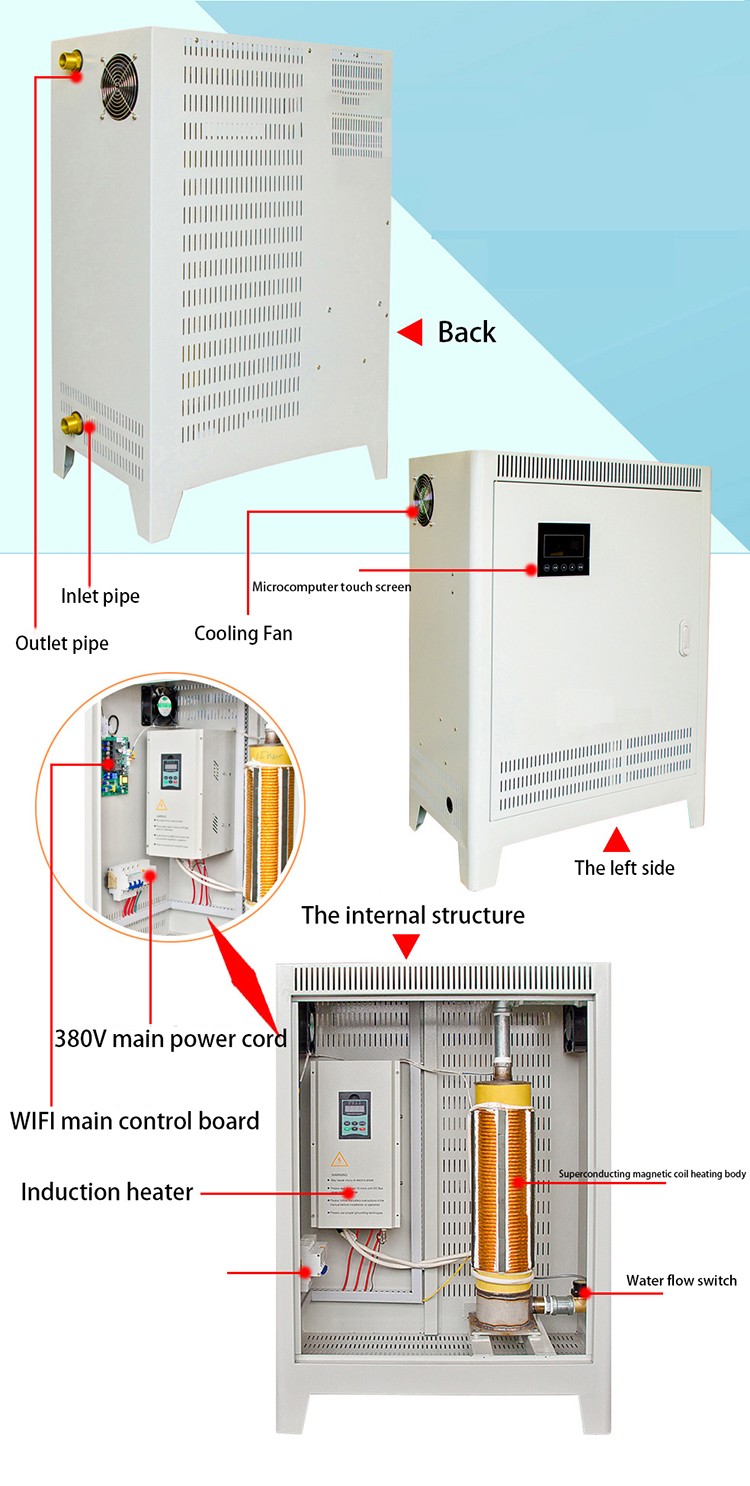

2. Safety: using the principle of heat generated by electromagnetic induction eddy current, water and electricity are separated, which is not easy to cause leakage danger, and it is safer to use;

3. Intelligence: high degree of automation, with the function of remote app detection and display of real-time data, including high and low temperature alarm, remote switch on and off and remote temperature adjustment, so as to reduce the investment of human resources;

4. Valley power storage: convert valley power into 95 ⊥ thermal energy storage;

5. Cost saving: using valley electric heating to reduce operation cost;

6. Power saving: three dimensional integrated heating, w (eddy current heating) s (short circuit heating) m (magnetic flux leakage heating)

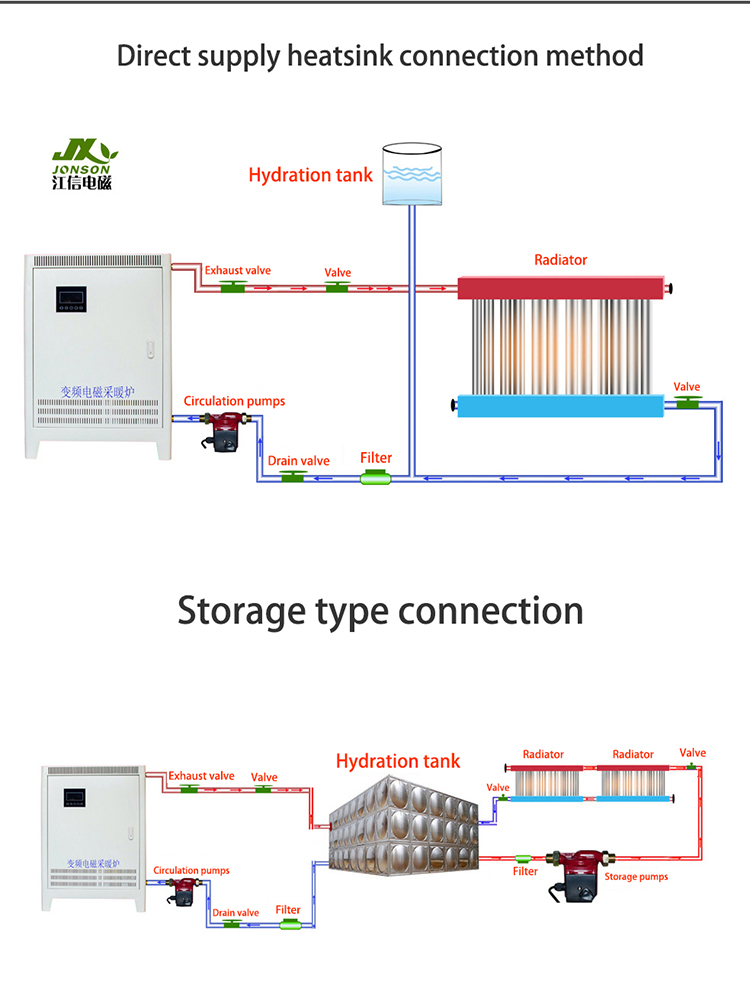

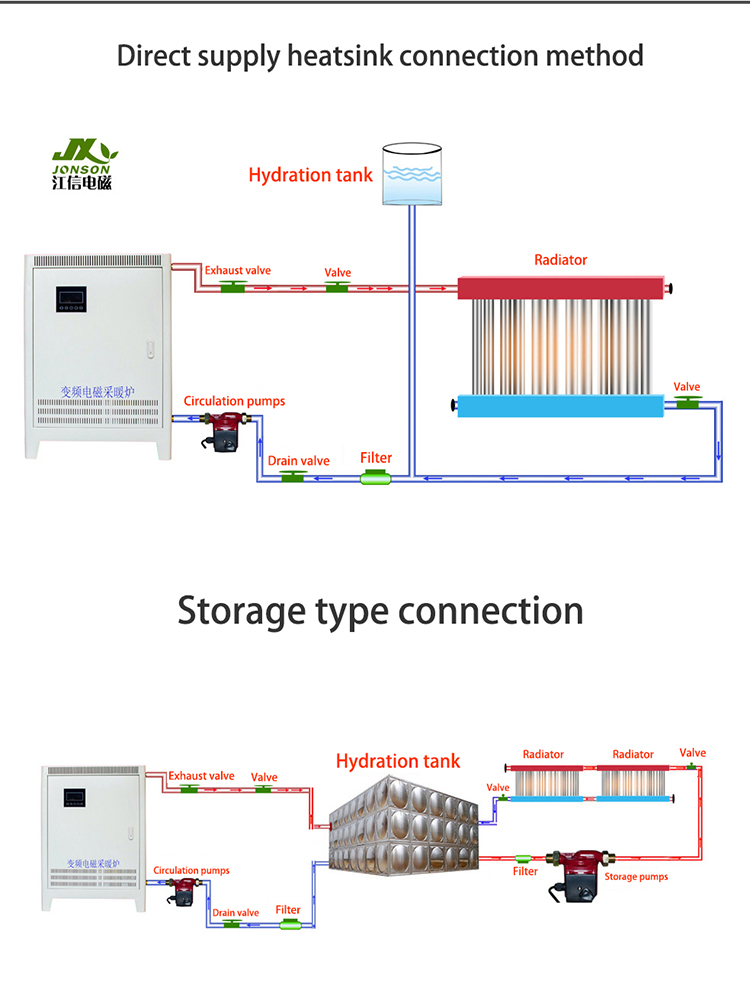

7. Replace the pipe network with power grid: reduce the heat loss of public pipe network and reduce the construction funds of public pipe network without road excavation;

8. Small size: modular combination, small floor area and reduced construction investment;

9. Simple management: it has the technical advantages of one key start, digital input, simple operation, full-automatic operation and so on;

10. Long life: it is designed and manufactured with industrial quality, and the system basically does not need maintenance;