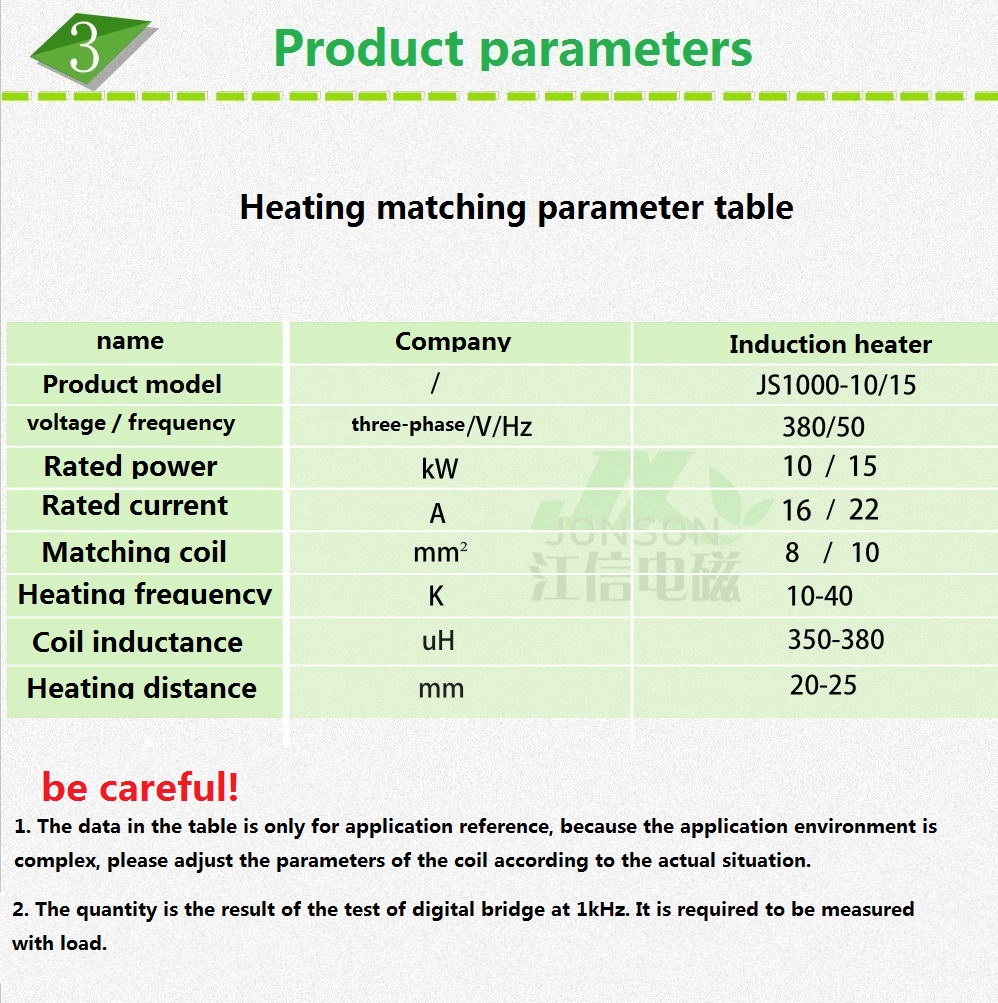

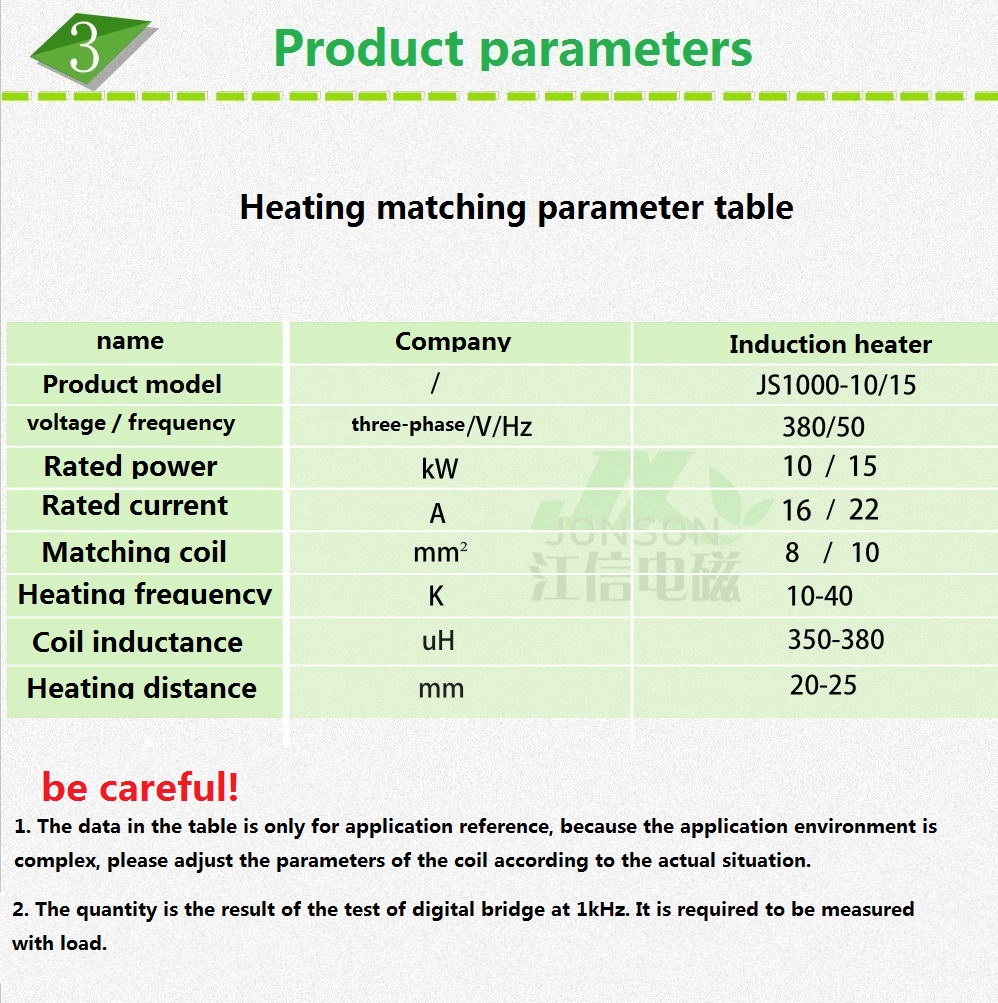

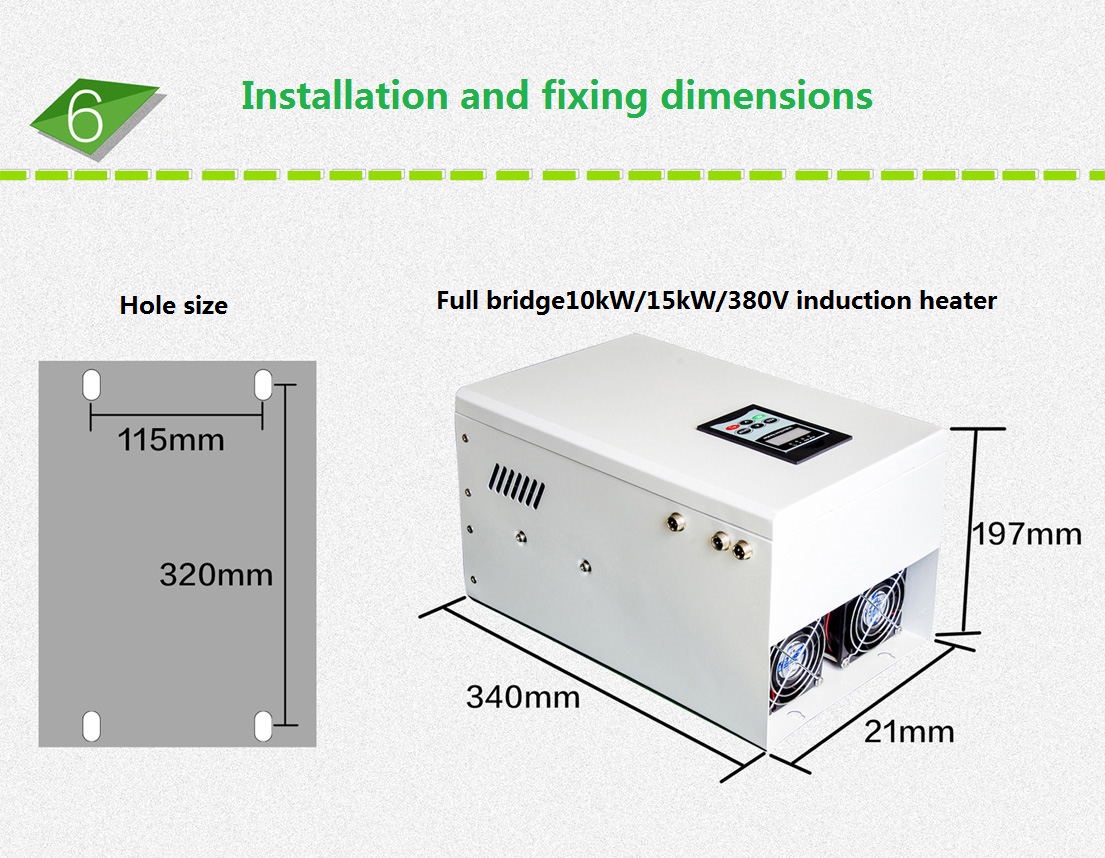

Full bridge10kW/15kW/380V induction heater Basic Info£º

rated power£º10KW/15KW Three-phase 380V

Rated input current£º10KW (14-15A) 15KW (20-22A)

Rated output current£º10KW (25-30A) 15KW (30-35A)

Rated voltage frequency£ºAC 380V/50Hz

Voltage adaptation range£ºconstant power output at 300 ~ 400V

Adapt to ambient temperature£º-20?C~50?C

Adapt to environmental humidity£º¡Ü95%

Power adjustment range£º20% ~ 100% stepless adjustment(That is: adjustment between 0.5 ~ 10/15KW)

Heat conversion efficiency£º¡Ý95%

Effective power£º¡Ý98%(Can be customized according to user needs)

working frequency£º5~40KHz

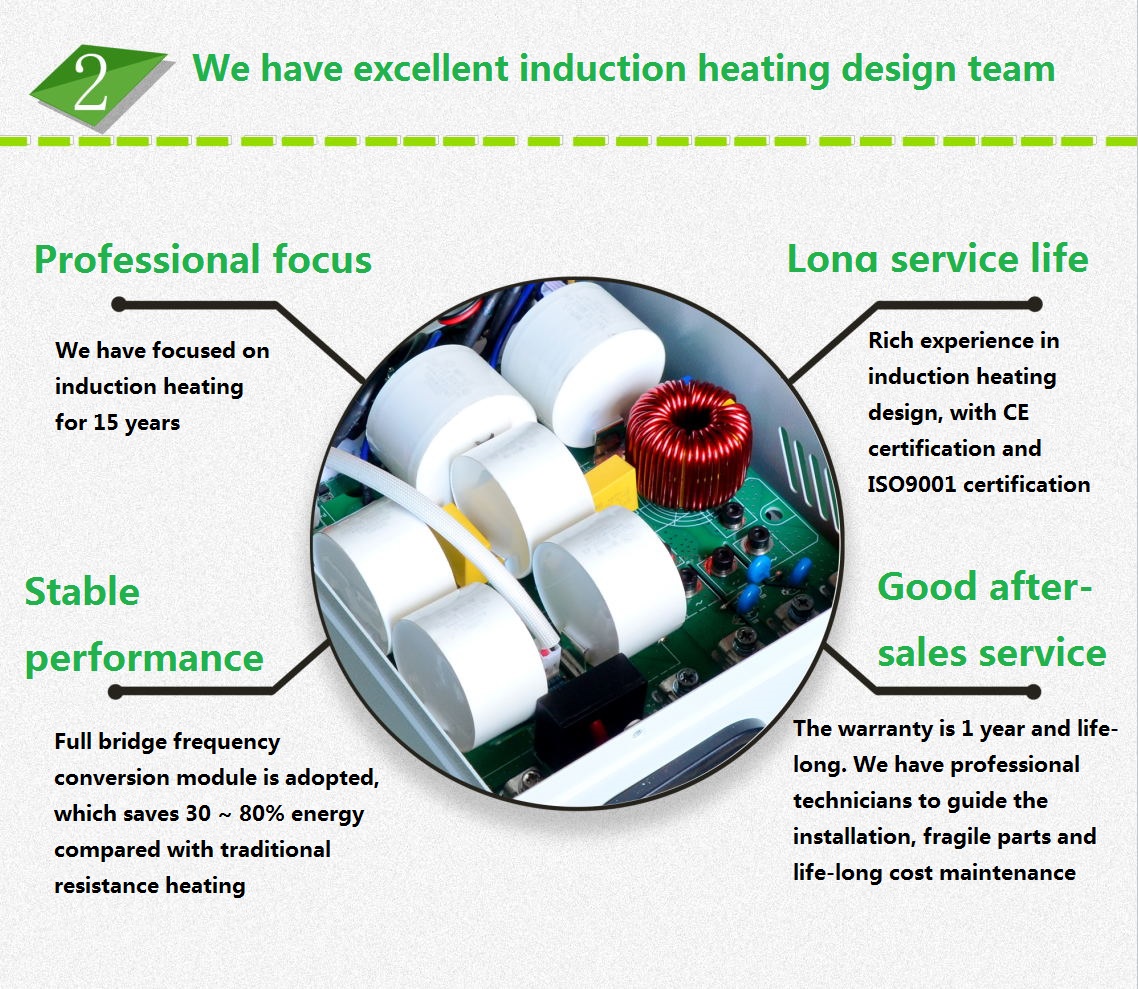

Main circuit structure£ºFull bridge series resonance

Control System£ºDSP-based high-speed automatic phase-locking tracking control system

Application mode£ºOpen application platform

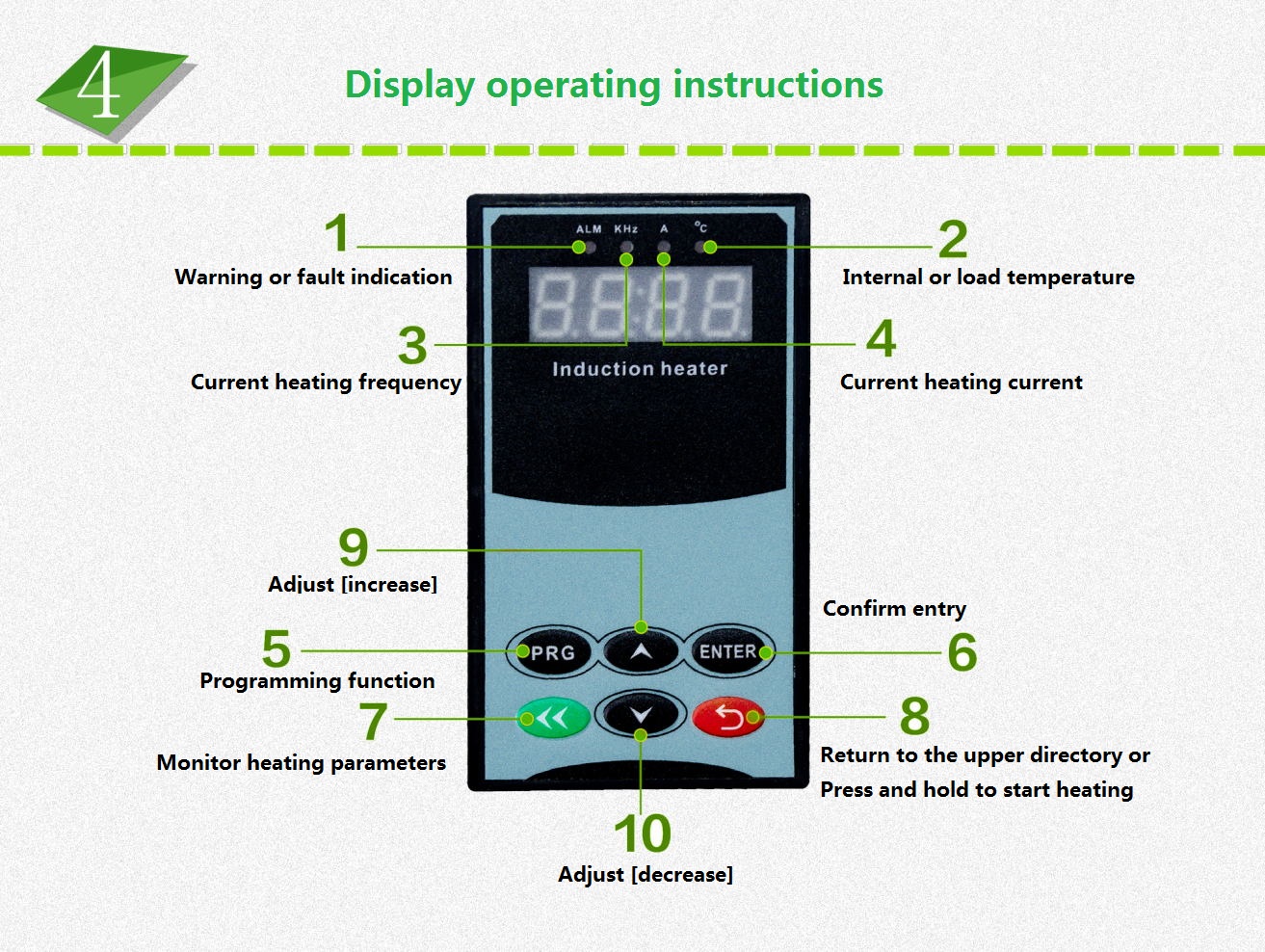

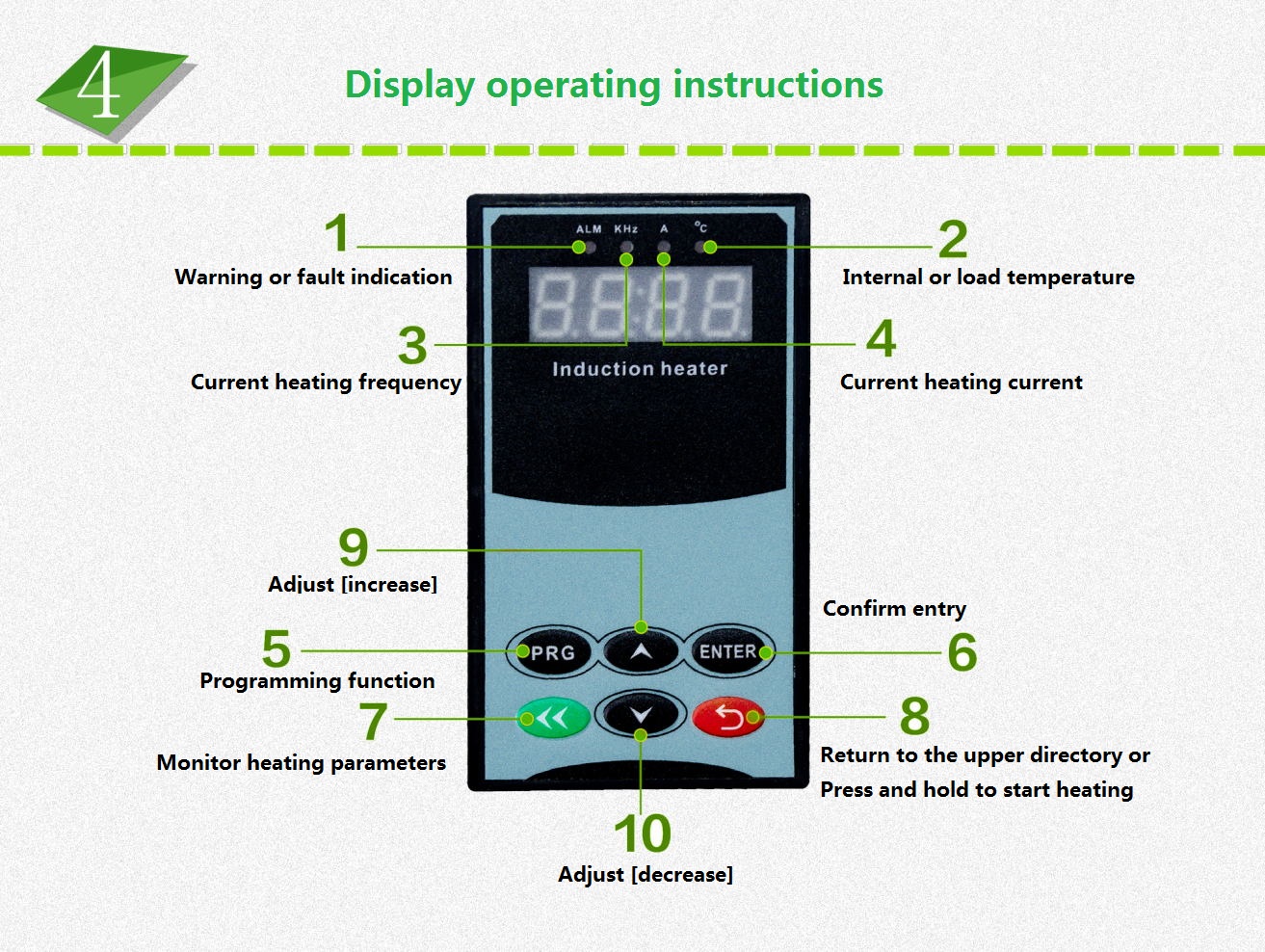

monitor£ºProgrammable digital display

start time£º<1S

Instantaneous overcurrent protection time£º¡Ü2US

Power overload protection£º130% instantaneous protection

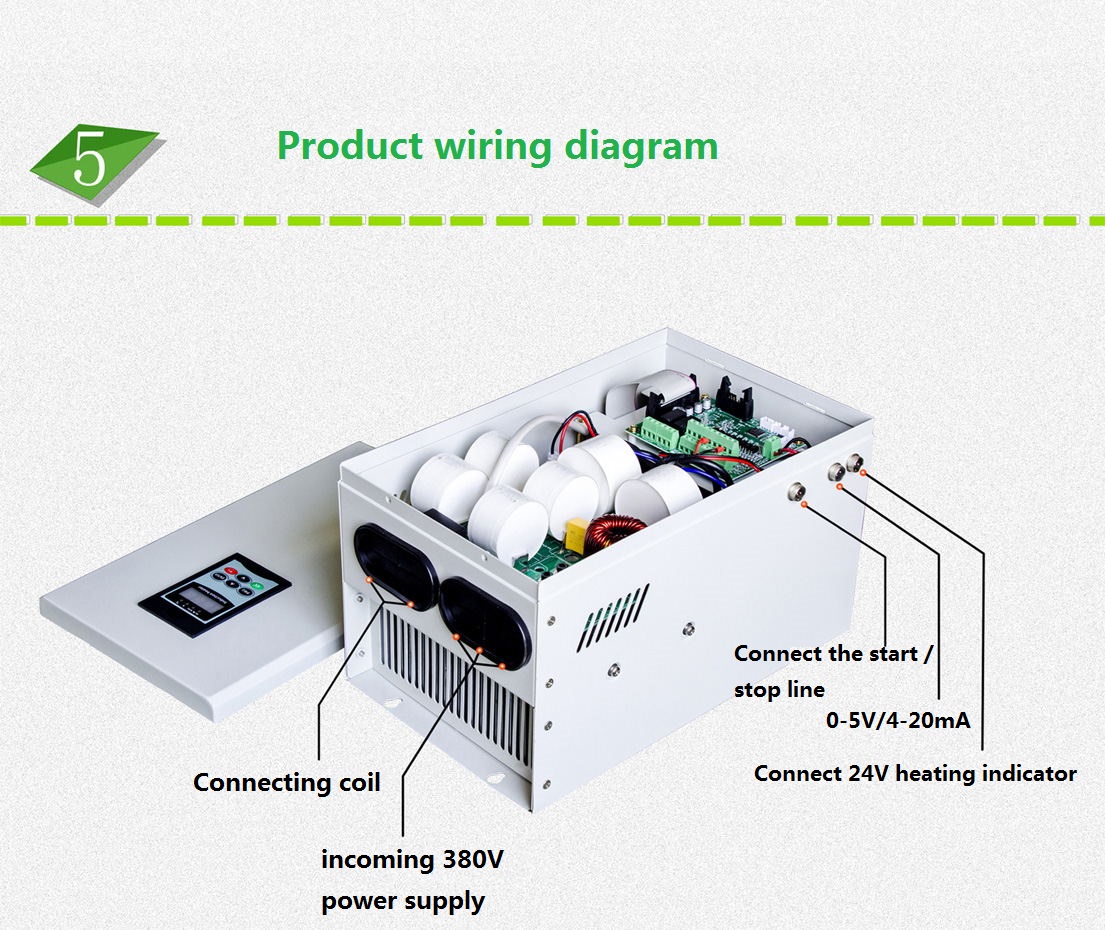

Soft start mode£ºFully electrically isolated soft start heating / stop mode

Support PID adjustment power£ºIdentify 0-5V input voltage

Support 0 ~ 1000 ?C load temperature detection£ºAccuracy up to ¡À 1 ?C

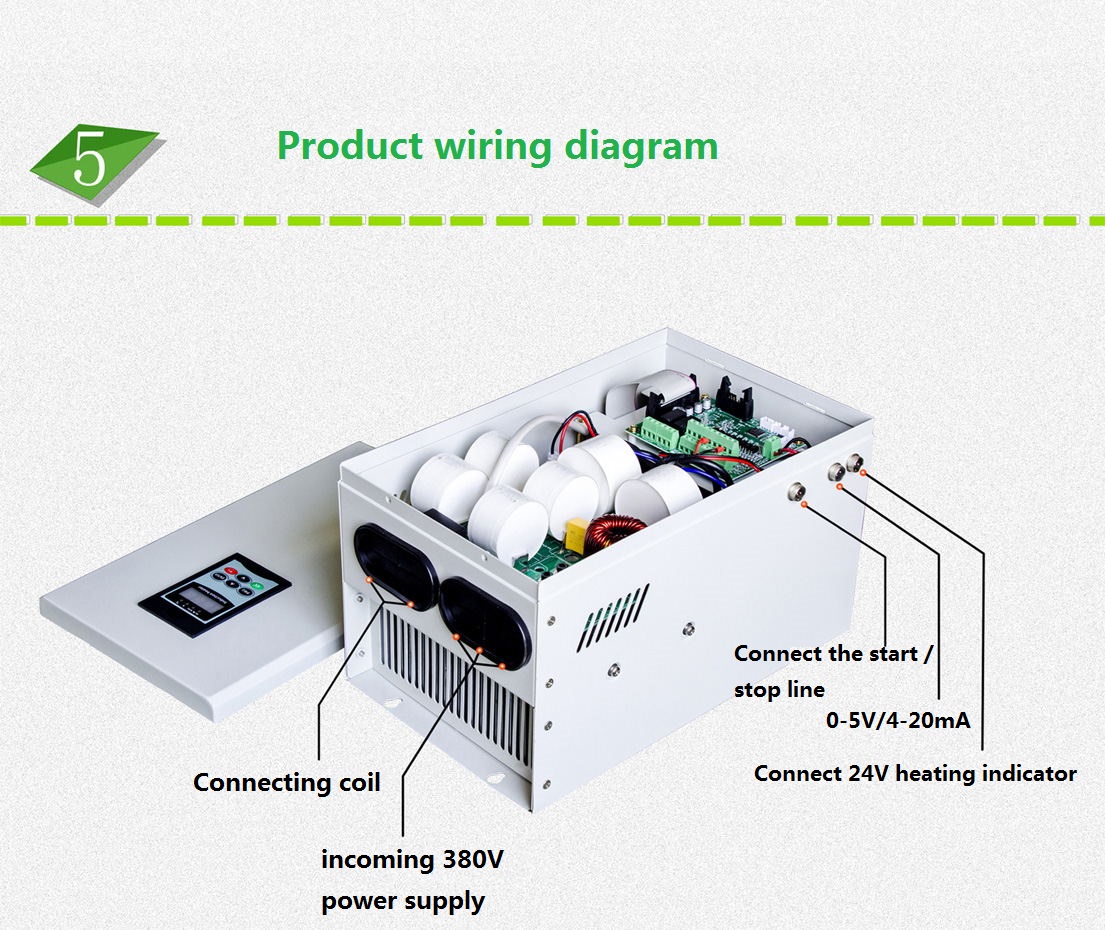

Adaptive coil parameters£º10KW 6 square line, length 60~80m, inductance 300 ~ 350uH

Net Weight£º10kg

°Õ°ù²¹»å±ð³¾²¹°ù°ì£º´³´Ç²Ô²õ´Ç²Ô

Transport Package£ºCarton / Wood Frame

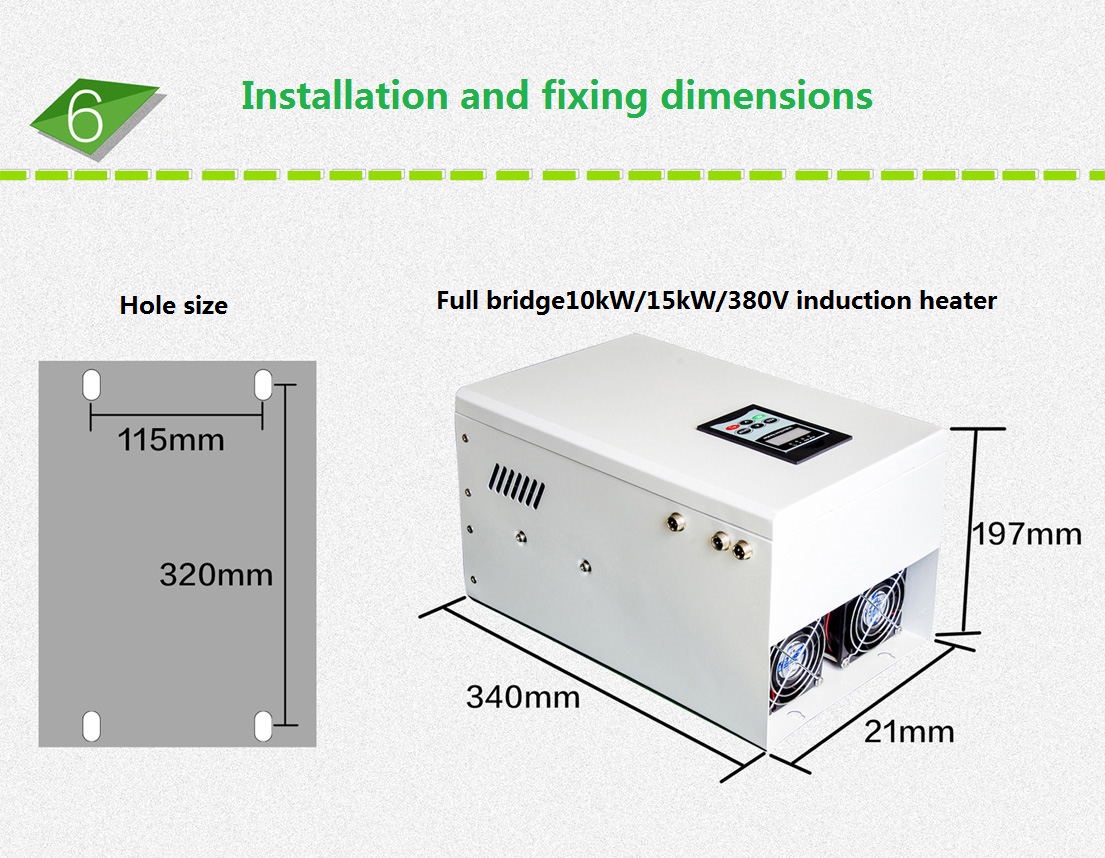

³§±è±ð³¦¾±´Ú¾±³¦²¹³Ù¾±´Ç²Ô£º340³¾³¾*210³¾³¾*197³¾³¾

Origin£ºGuangdong Province, China

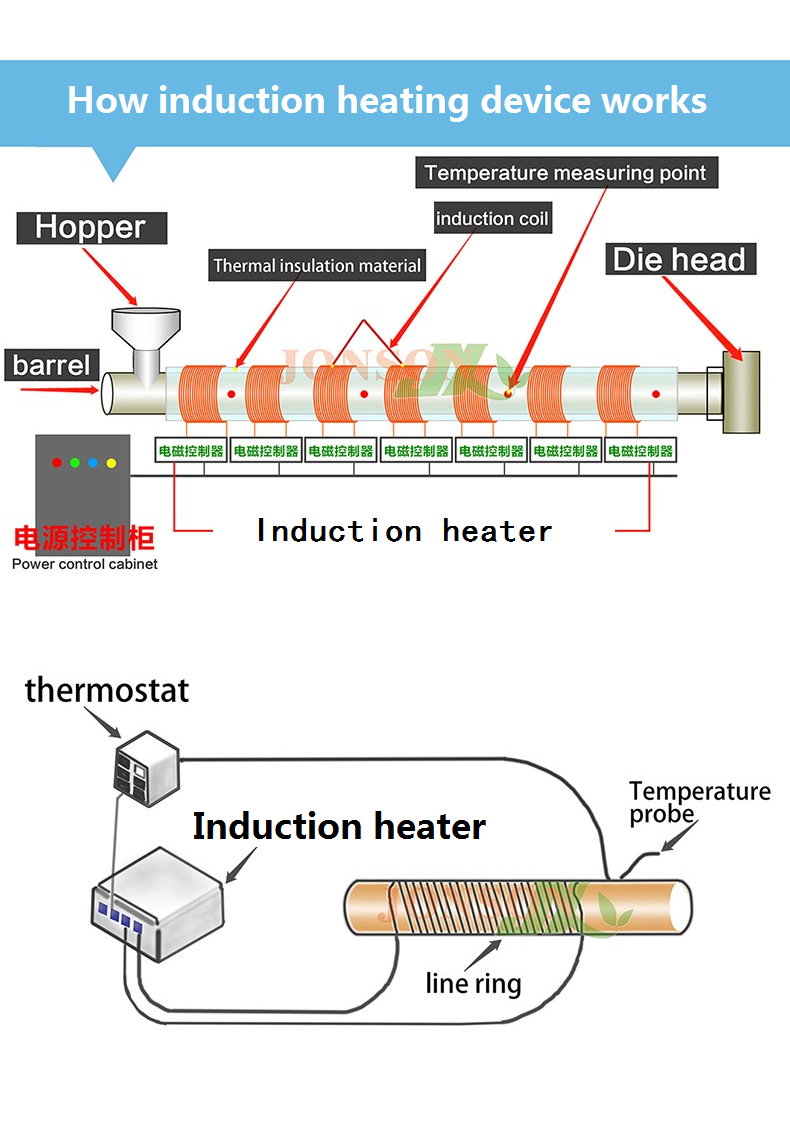

induction heater Description

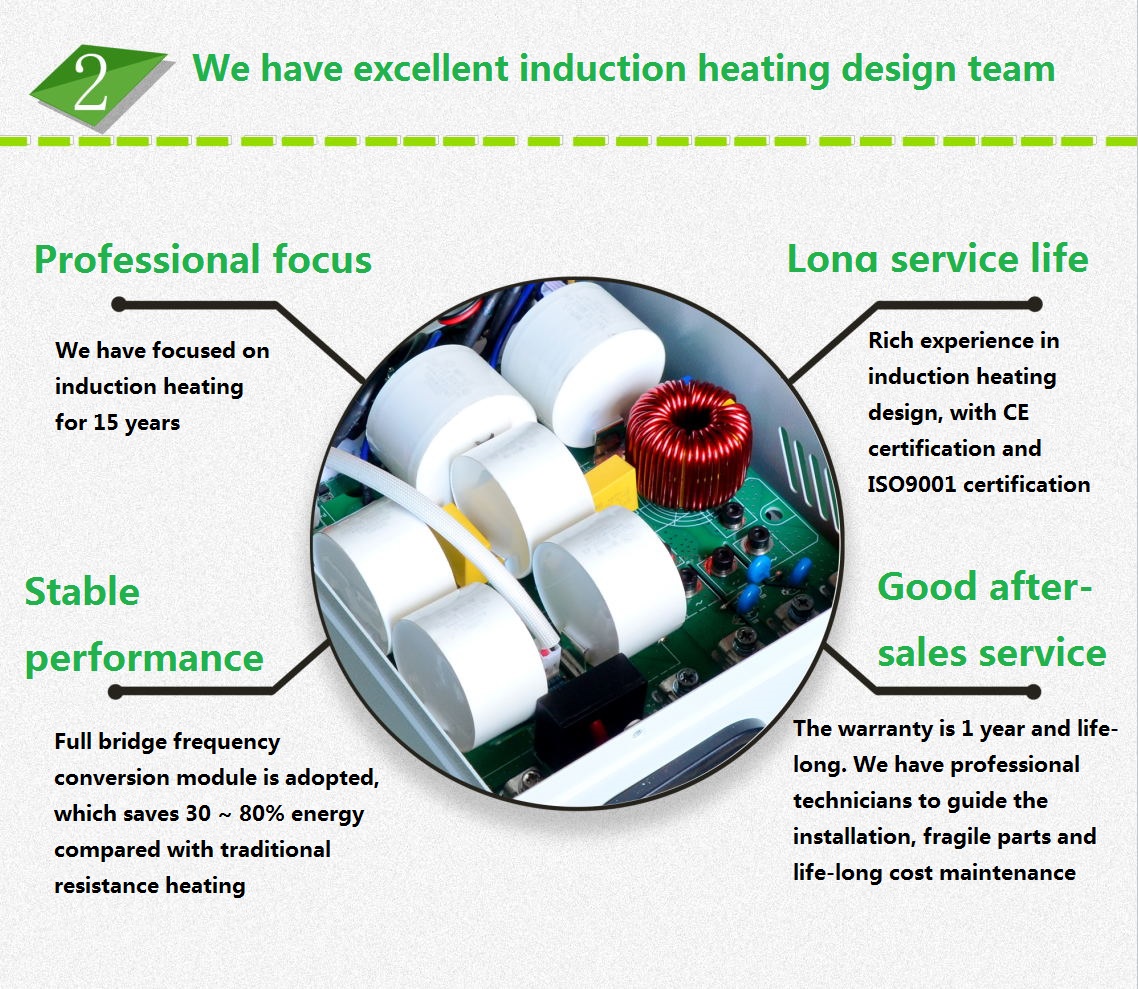

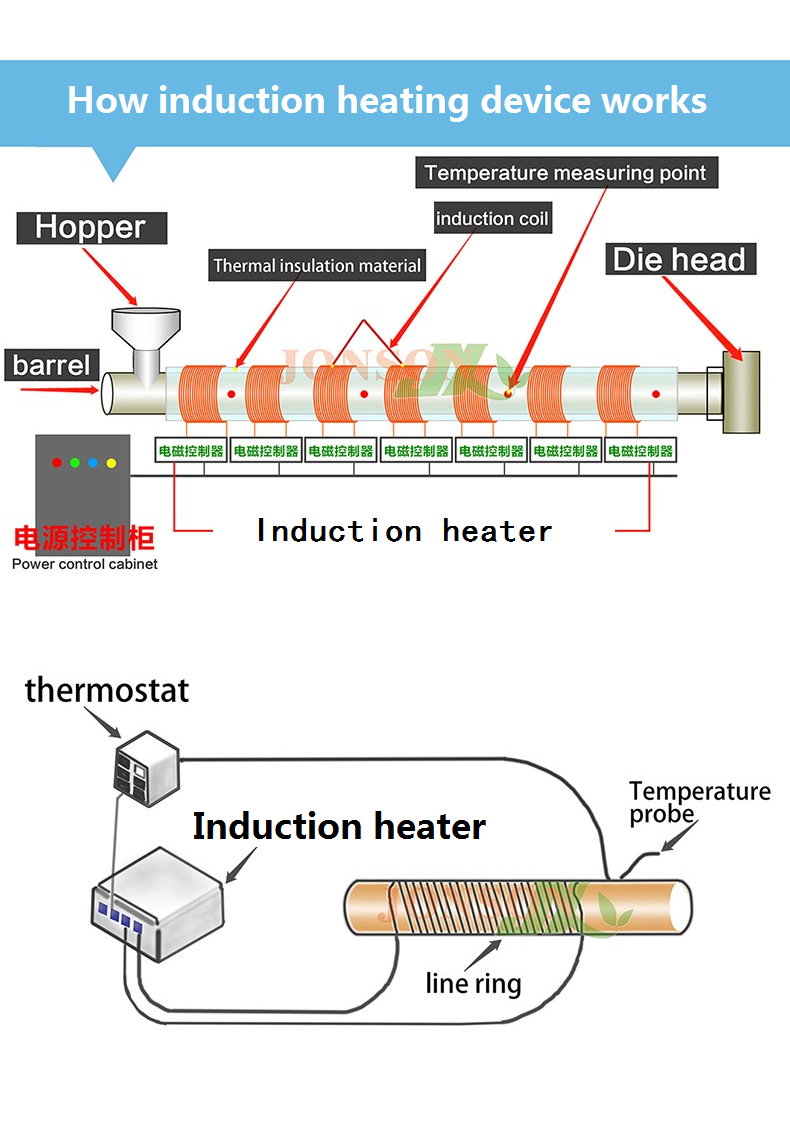

Induction heater 10kw/induction heater 15kw has evolved from a single heating tool to a core process equipment in the era of Industry 4.0. The high efficiency, precision and environmental protection of induction heater 10kw/induction heater 15kw are reshaping the traditional manufacturing industry ecosystem.

User value and cost analysis

1. Induction heater 10kw/induction heater 15kw increases economic benefits

Reduced energy consumption: Taking 1 ton of metal smelting as an example, induction heating saves 80,000-120,000 yuan in electricity bills per year compared to traditional electric furnaces.

Maintenance cost: The life of core components is >10 years, and the annual maintenance cost is only 1/3 of that of traditional equipment.

Return on investment: The investment recovery period for small and medium-sized equipment (50-500kW) is 1-2 years.

2. Induction heater 10kw/induction heater 15kw increases environmental benefits

Zero emission: no combustion exhaust gas and dust, in line with carbon peak policy requirements.

Space saving: 50% reduction in volume, reducing plant floor space.

3. Induction heater 10kw/induction heater 15kw can improve process

Product quality: temperature uniformity is improved, and the defective rate is reduced by 10%-20%.

Production flexibility: modular design, support for multi-process switching, and adapt to small batch customized production.

Intelligent Control

All digital phase-shifting intelligent control, support RS-485 communication,adopt German IGBT frequency conversion 17³Ô¹Ï. durable and reliable quality

Multiple Protection Functions

IGBT module overheating insulation degree: 80C

Overload capacity is 150%

Under voltage and over-voltage protection

Coil open circuit, short circuit and phase loss protection

Flexible Application

Coil intelligent identification 17³Ô¹Ï automatically adjust the output to achieve the ideal working state

Energy Conservation

With electric energy as fuel, it has no emission andpollution, can work alone, and can use low-costelectricity to save energy greatly

It can be heated for 304 stainless steel materia

We have special induction heating 17³Ô¹Ï, which can heat weak magneticmaterials such as 304, 310, 316 and 310S, which can meet the application ofspecial industries such as food, medicine and chemical industry